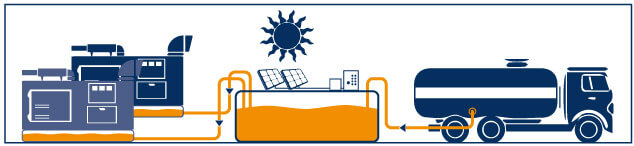

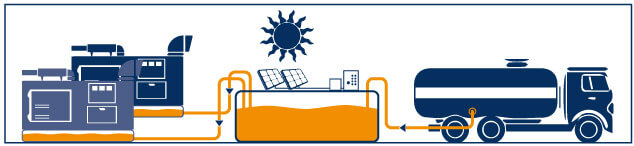

PETRO Industrial custom fitted this 11,000L PETRO Fuel Tank with a Dual Solar Powered Pump System to serve as a day tank.

Accompany Mark, our Major Projects leader, on an exclusive tour of one of our specialized, compact projects.

Introducing the PETRO Self Bunded Tank, meticulously designed to ensure the continuous operation of 2 Generator Sets, all fully automated.

Equipped with a tailor-made electrical board, an impressive array of solenoid valves, a cutting-edge solar inverter, a dependable deep cycle battery, state-of-the-art high and low-level alarms, and a high-performance battery charger – this is the ultimate, all-inclusive solution.

THE PETRO BUILD

The Tank is fitted with a 12 Volt Solar Powered System which consists of:

- 2 x Solar Panels.

- Solar Converter.

- Battery Charger as back up.

- Electrical Control Board where the pumps can be controlled manually or automatically.

- 2 x 12V Pumps.

- 2 x Solenoid Valves on Suction to avoid syphoning.

- 2 x Foot Valves and Strainers.

- Bridging Solenoid so that either pump can operate both systems in the event of one pump being down.

- Low-level probe to shut down the pumps and set off an alarm when the fuel level reaches the low-level point.

PETRO Industrial has the capacity to tailor commercial refuelling solutions to your business' applications.

Check out this short video below, detailing the build of a PETRO T11 Dual Generator Feed tank:

You can always rely on PETRO for a solution!

1300 978 789

TRANSCRIPT:

"Ok, we’ve got a project here which is an 11,000 litre Self Bunded Fuel Tank, set up for daytank transfer.

So what we are doing is, feeding two generators.

This application is 12Volt, so we have solar power. Two solar panels down there, solar converter here, battery charger under here as a backup.

Electrical control panel, so we have duty standby pumps, so our Control board is capable of automatic and manual pump control.

Here we have Pump 1 and Pump 2 selection. Controls here to manually start and stop the pump from priming.

So stepping back through here, everything is controlled by 12 Volt solenoid valves and all linked back to the electrical control board.

So what is happening, is we have pump one, pump two, we have solenoid valves on either side of the suctions to control syphoning or to avoid syphoning.

We have foot valves in the tank, we have strainers. We also have a bridging solenoid here so that either pump can operate in closed systems.

So, in the event that one pump is down, we can supply two lines. We have set our solar panels up on top of the tank as you can see there.

We have a low level probe over here. So this probe this sensing fuel in the tank, it will shut down should the tank be on low level and set off an alarm, protect the pumps.

So this is it."